With over 25 years in the custom precision machining and metalworking field, mSQUID has earned its place as a true industry leader.

Through the decades, our clients have come to rely on our ability to produce professionally machined products and to provide them with the components and tools they need to keep their businesses thriving in an ever-changing world. With this in mind, our company has broadened its horizons to expand our services to the national and international marketplace. We are now more prepared than ever to meet the component manufacturing needs of the global industrial community.

Industrial sectors

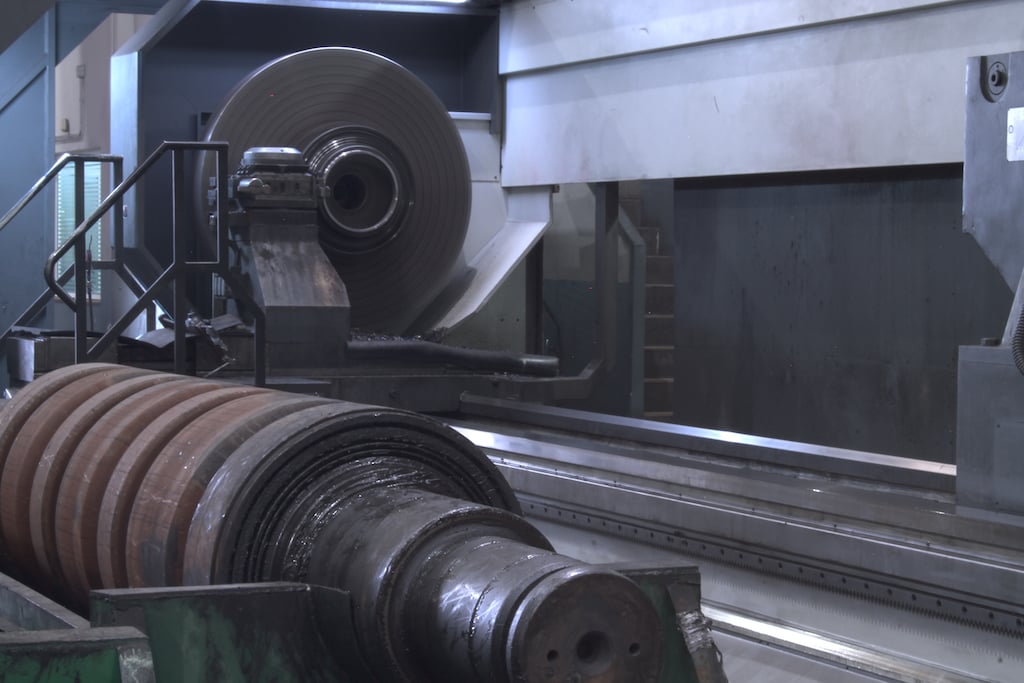

Metallurgy Industry

Repair and manufacture of equipment and components for metal foundry and its derivatives fabrication is one of our cornerstone services. Our clients depend on us whenever they need quality components for their processes and machinery needs. Whether for rolling or casting, the demand for top-notch precision, accuracy, and reliability is a must to stay ahead of the competition.

Our technical team will work with you to creatively design machined alloy components, production welding accessories, gearboxes, rollers, turning machine components, and custom structures used in steel beam formation and other processes. These components are designed to be compatible with your existing machinery and made with high-grade materials to ensure ultimate durability.

Paper industry

The paper industry is one of the most important industrial sectors in the world. mSQUID has played a pivotal role in its advancement with our deep understanding of the technical requirements needed for customer success within this field.

Here at mSQUID, we have the experience and ability to manufacture and supply the precision parts needed to get large scale paper production jobs done quickly and efficiently. We provide machined parts such as drying cylinders, headboxes, impellers, slotted baskets, roller mills, and other cold press components. The construction of this type of machinery relies on precise measurements and components with high output capacity. Our machined parts provide our customers in the paper industry with all the confidence and quality needed to deliver high-quality paper-based products.

Cement industry

As an essential building material, cement is the basis on which many high-rise buildings and homes are built on. We understand the cement manufacturing process is a complex one and is known to place extreme wear and tear on the tools and machinery used to produce this product. Repetitive mining and grinding of raw materials such as limestone and clay into meal requires the use of only the highest quality components.

Because of our understanding of this critical industry and the cement creation process we are equipped to provide you with all the custom components needed for blending, storing, and milling of your product to ensure that you are providing the highest quality service for your clients while achieving operational success.

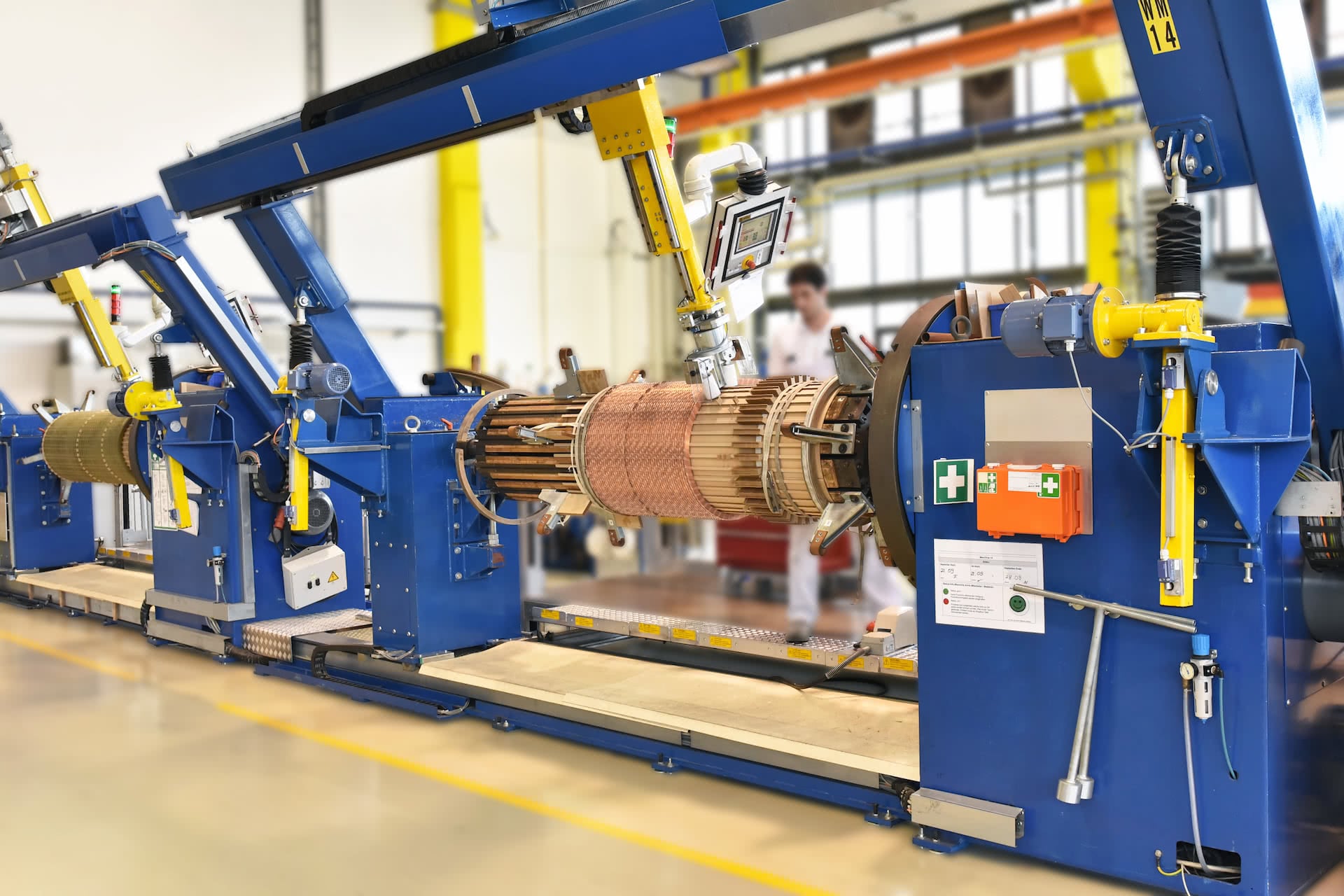

Wiring industry

Metal wiring, whether for communications, structural construction, is constantly increasing in demand. These multiple facets of wire applications make the wiring industry a key player in the advancement of new and existing communities.

Such an important role requires manufacturers to be ready to meet and exceed the demands of these jobs by ensuring they have quality machinery available. Precision and accuracy from quality components must be achieved in all steps of the process

Our technical team will design, implement, and fine-tune all the equipment components your wiring machinery needs to keep your industrial cabling business going.

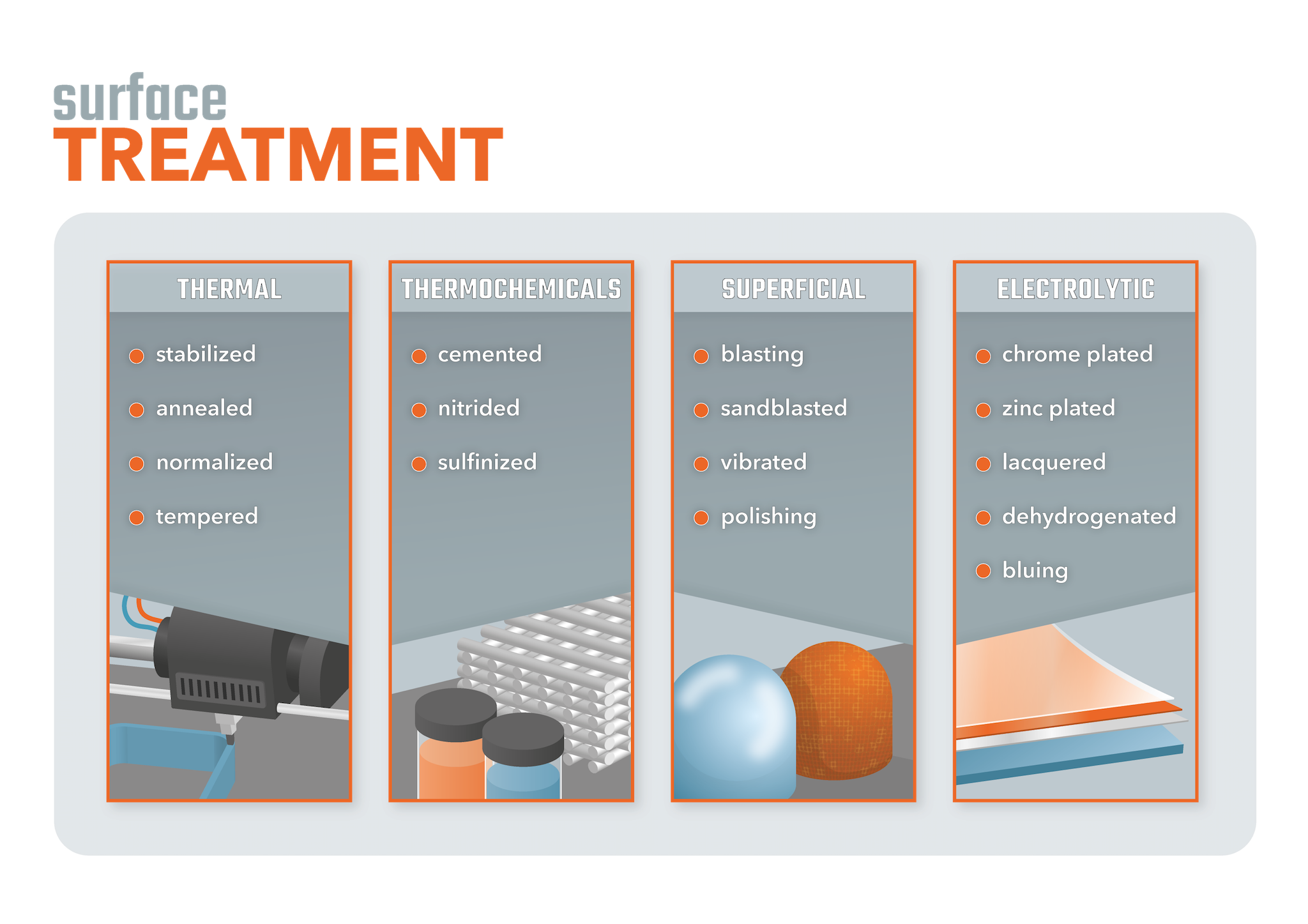

Complementary services

Technology and precision are at the forefront of every job we do. That's why our Engineers offer an array of complimentary services to support each project’s needs and allow us to create a completely customized experience for every customer. This includes 3D scanning of objects with pinpoint accuracy, CAD-CAM programs, and other computer based technologies that can be used within advanced manufacturing and machining that allows us to produce overly complicated components with extreme precision. We take a multifaceted approach to each job and consider all outcomes and efficiency improvements while we work with you to create the components you need for success.

Renewable energies

The wind sector is one of the industrial sectors declared of strategic interest by the EU within its energy sustainability agenda framed within the 2018-2050 directive for the development of a decentralized cross-border renewable energy production network.

mSQUID enters as a strategic 'partner' for wind farm operators developing optimal methodologies and systems in several key areas of wind turbine assembly and maintenance, both in their anchoring and assembly structures and in critical components in the energy transformation sequence mechanical in electrical.

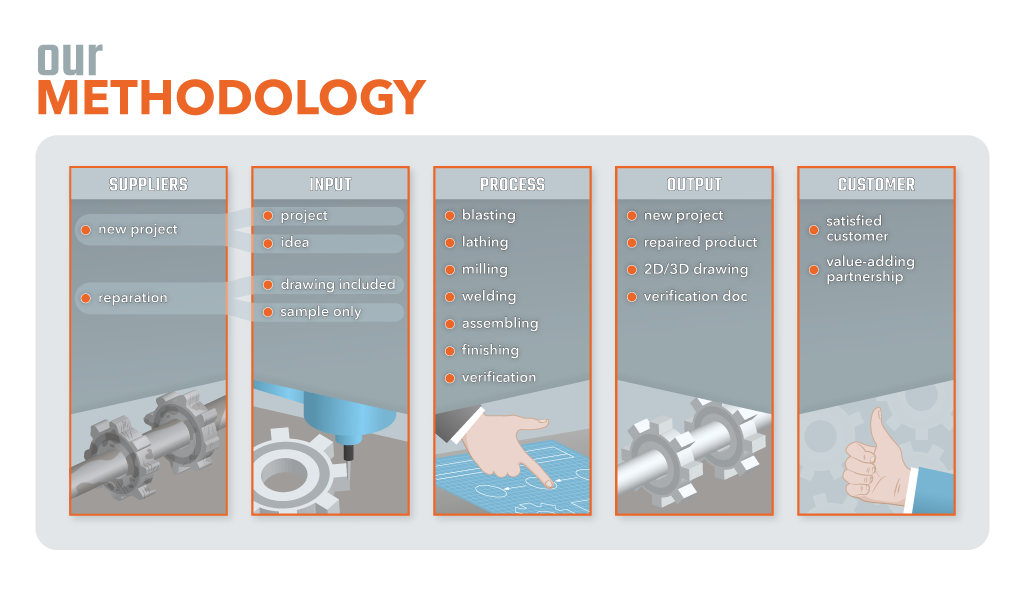

Methodology

Maintenance line

Preventive maintenance and repair of mechanical components, either on a scheduled basis for production lines subject to regular deterioration and wear or for specific cases of breakage, collapse or extinction of one or more elements within a mechanical device.

At mSQUID we can develop the entire process to obtain new or renewed parts from technical drawings or, in their absence, from new or damaged samples.

Line of new developments

The development of new devices and parts from an idea proposed by the client together with its corresponding set of specifications and requirements for which we carry out the engineering project or, from an engineering project already validated that the client gives us.

Once the project processing line is executed, the client will receive their new product or its repaired component, the pertinent 2D / 3D graphic documentation together with the documentation derived from the quality verification process.

The quality of our production process, together with the clarity and transparency with which we communicate the development and verification processes, promote long-term relationships with our clients with a high degree of satisfaction, which is why we become suppliers with a high value-adding for continuity of your industrial operations.

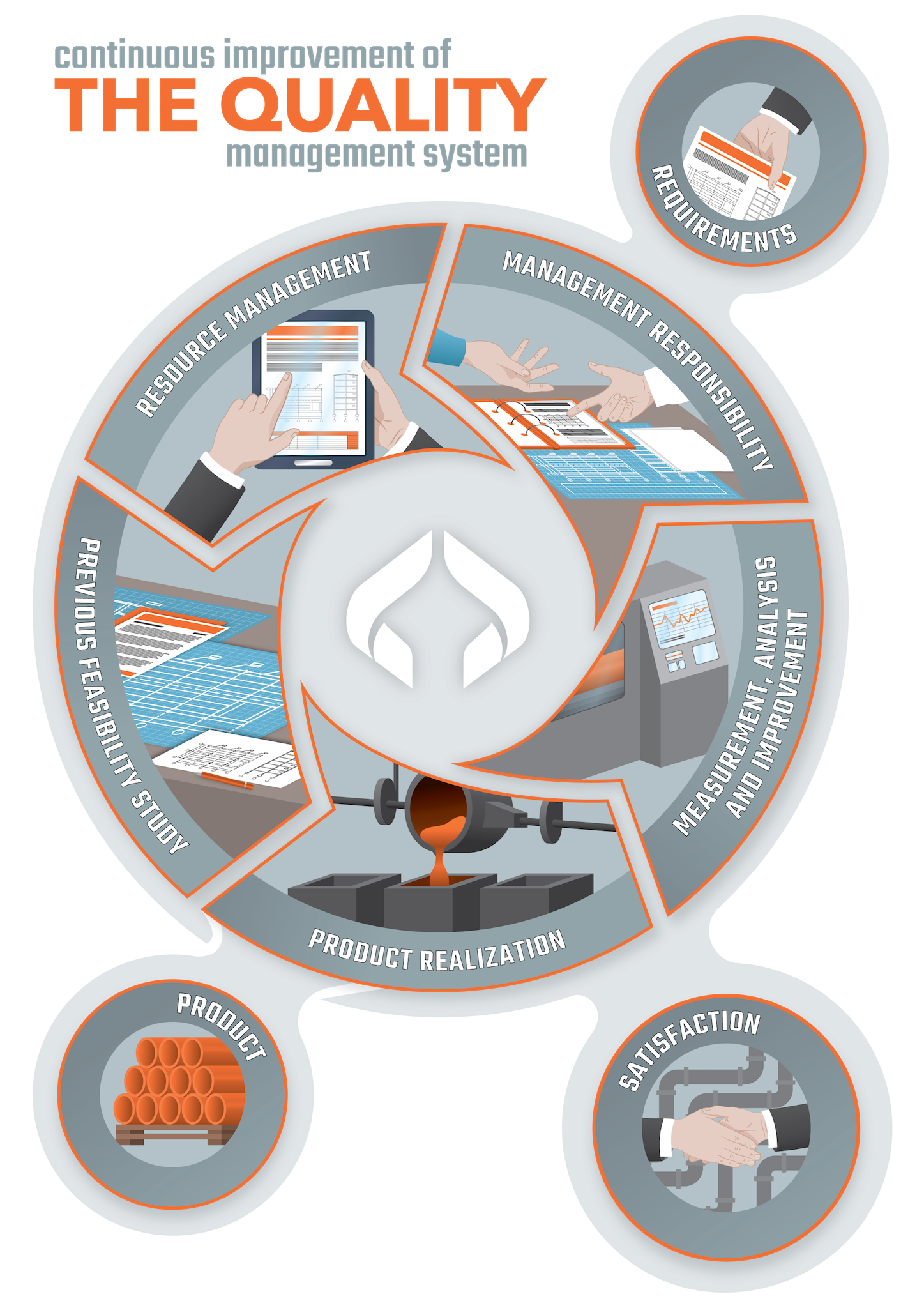

What You'll Get

Our commitment is twofold: on the one hand with the quality of the services we offer, which must comply with the standards established by the norm and, on the other hand, with our clients. We work by and for them, pooling knowledge and experiences to consolidate our joint path towards the future.

Range of Services

Lathe

We have a park of machines for single manufacturing or for serial production of small or large parts, according to customer needs.

We are used to working with all kinds of materials such as steel, stainless steel, wear resistant materials, bronze, copper, cast iron or technical plastics.

Mounting

Milling

Our machines allow maximum dimensions of 5 meters in X, 1.2 meters in Y and 2 meters in Z. Equipped with a tool loader, fourth axis and centesimal turning head.

Painting

Welding

We also recharge with anti-wear materials on both flat and cylindrical surfaces.

We are certified according to DIN EN ISO 9606-1∶2017 and we collaborate closely with the best machinery and thread manufacturers on the market.

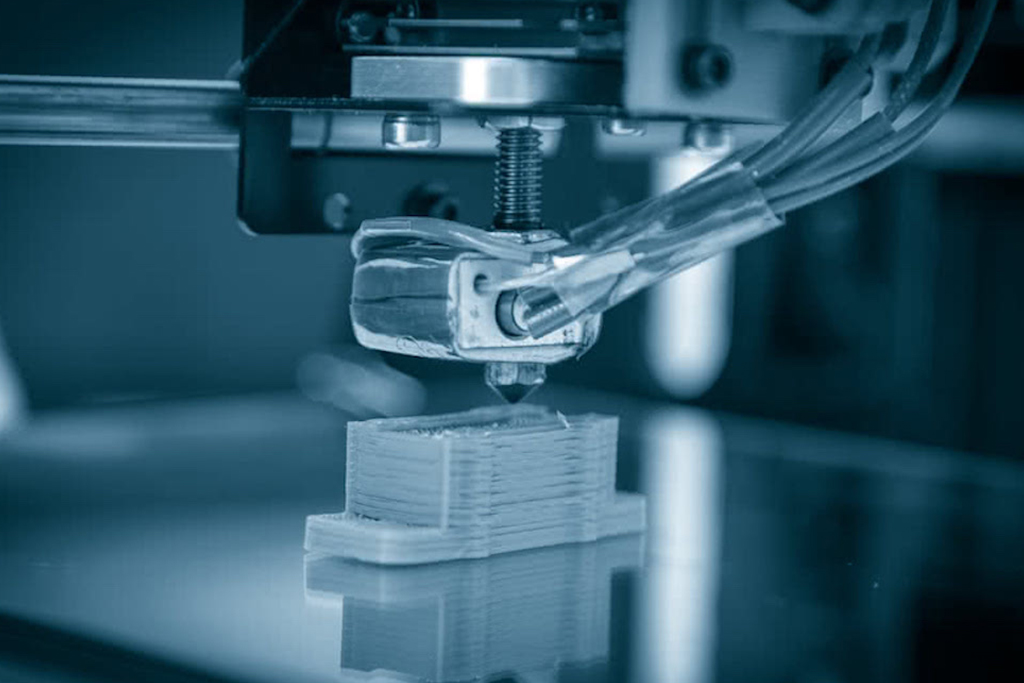

Prototype 3D printing

+34 93 770 80 86

+34 93 770 80 86